Sol Stainless Steel Turning Recommendations

Release time:

2022-11-21

Three Difficulties in Stainless Steel Processing 1. Work hardening: stainless steel will harden during cutting, and the work hardening phenomenon caused by the previous feed or previous process will seriously affect the smooth progress of subsequent cutting.

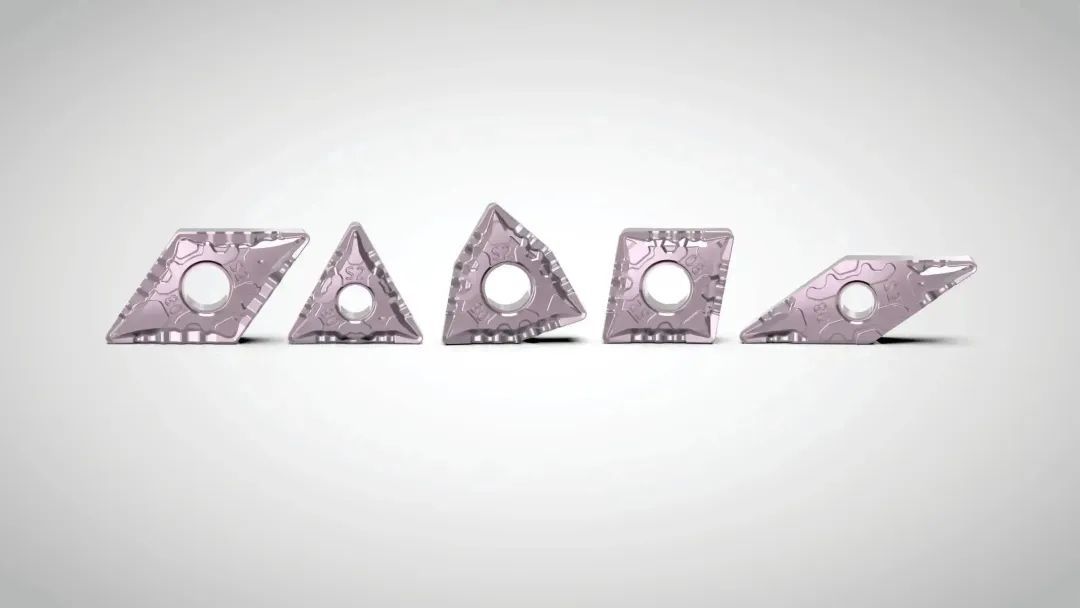

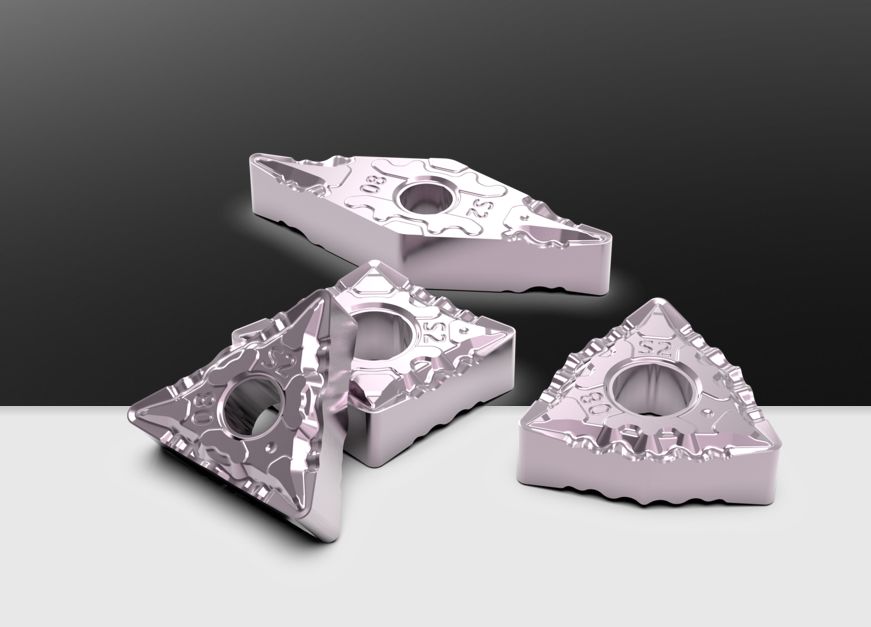

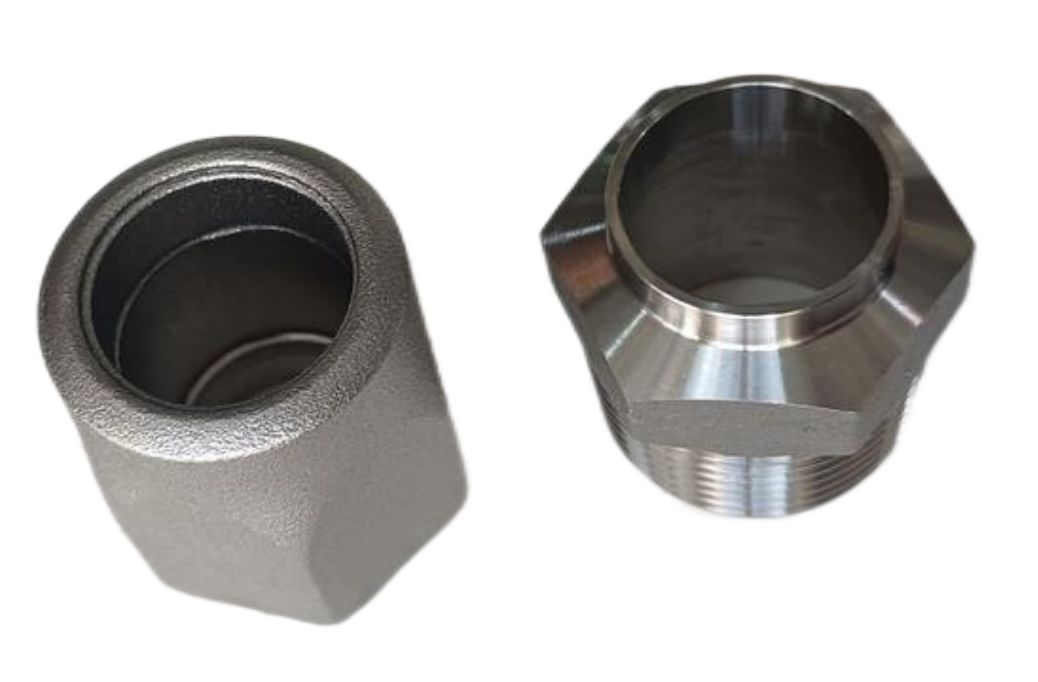

Stainless steel turning

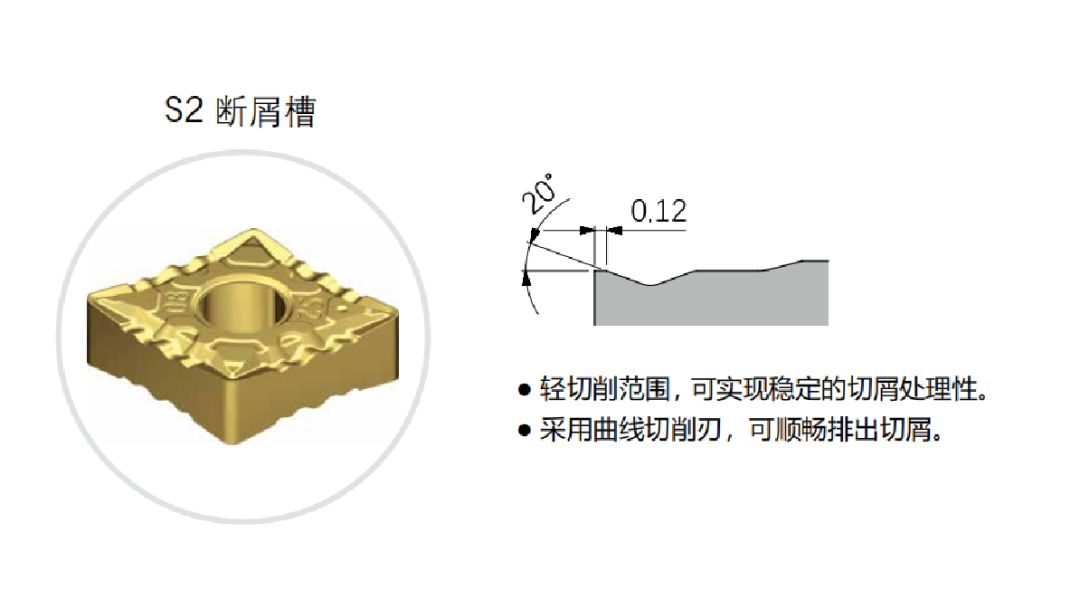

S2 series

Groove advantages

Three Difficulties in Stainless Steel Processing

1. Work hardening: stainless steel will harden during cutting, and the work hardening phenomenon caused by the previous feed or previous process will seriously affect the smooth progress of subsequent cutting.

2. High cutting force: stainless steel has large plastic deformation during cutting, especially austenitic stainless steel (its elongation is more than 1.5 times of 45 # steel). While the cutting force is increased, the thermal strength will also be improved, and the curling and breaking of the chip is more difficult to further increase the cutting resistance.

3. Chip breaking difficulty: stainless steel has strong plasticity and toughness, and chips are not easy to break and bond, which not only affects the smooth operation, but also damages the machined surface. Under high temperature and high pressure, stainless steel has a strong affinity with other metals, which is easy to cause adhesion and form chip accretion, which not only aggravates tool wear, but also causes tearing phenomenon and worsens the machined surface.

Sol S2 series, dealing with stainless steel processing problems

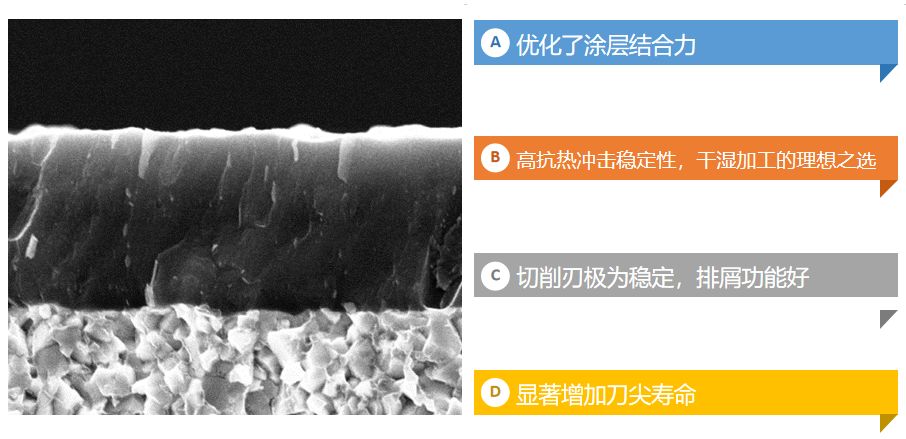

Brand advantage

The new nanostructure TiAlSiX coating is combined with the sub fine grained cemented carbide matrix with high Co content, which has excellent anti scaling characteristics and anti collapse property. Suitable for semi precision to rough machining of stainless steel; Threading of steel, stainless steel and other general materials.

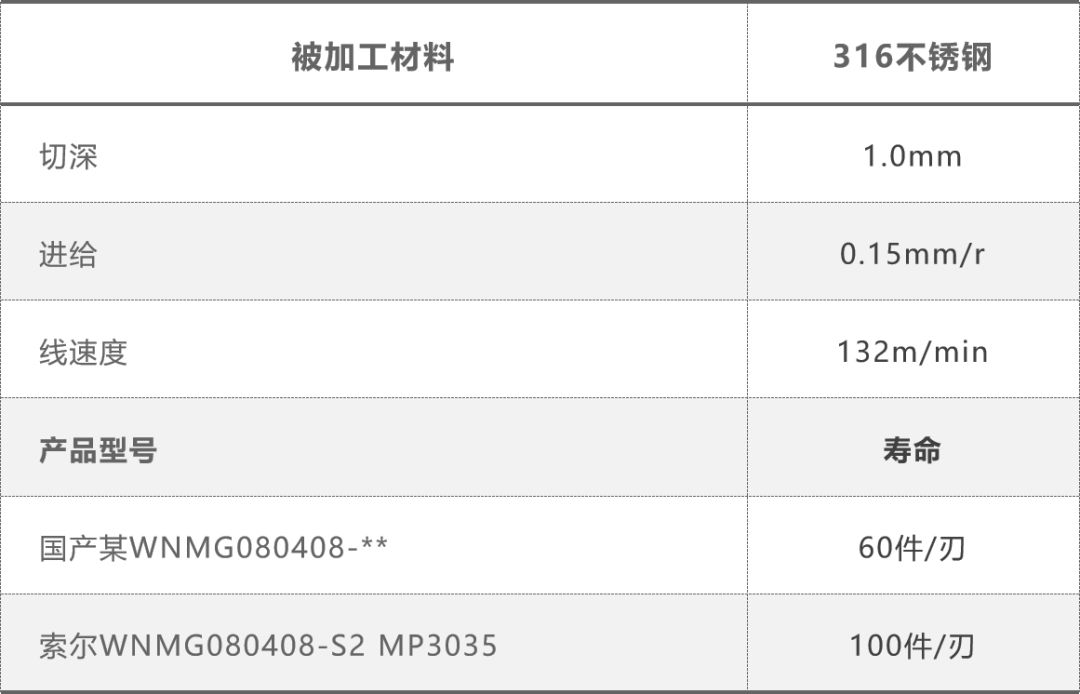

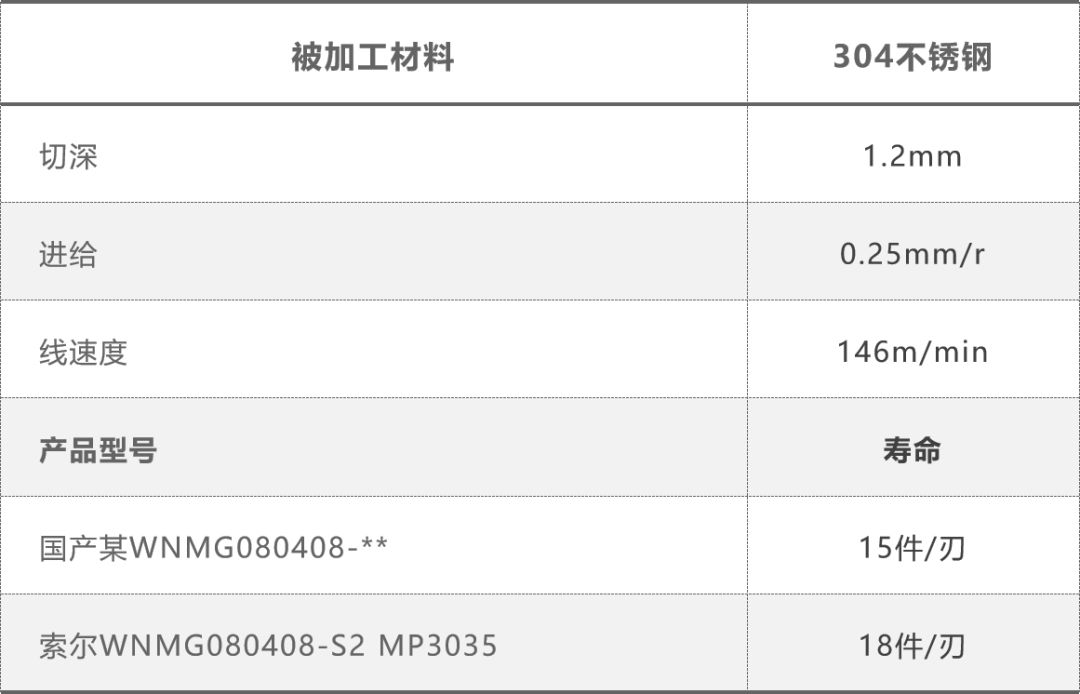

Processing cases

1

2

3

Related news